Product Description

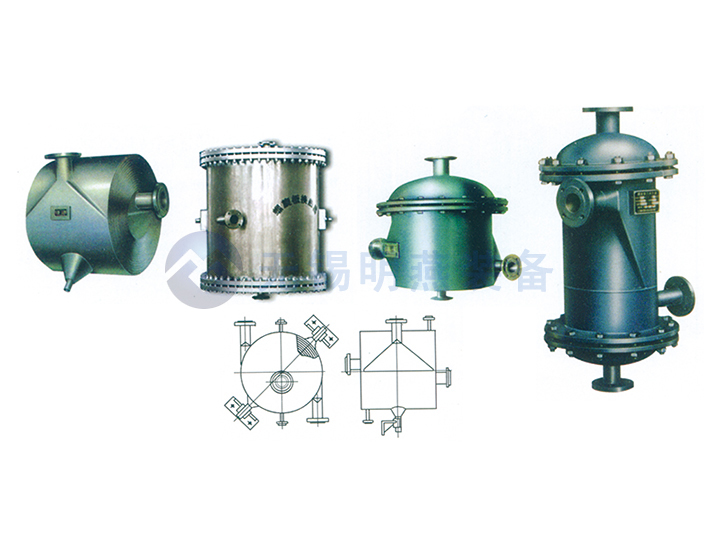

Spiral plate heat exchanger is a kind of heat exchange equipment, suitable for gas-gas, gas-liquid, liquid-liquid, as well as heat transfer for condensation and liquid evaporation. The product has the advantages of high heat transfer efficiency, strong dirt self-cleaning ability, good effect, small size, low price, and reliable use. Products are widely used in chemical, petroleum, solvent, medicine, food, light industry, textile, metallurgy, steel rolling, coking and other industries. According to the structure, it can be divided into non-detachable (type Ⅰ) spiral plate heat exchanger and detachable (type Ⅱ, Ⅲ) spiral plate heat exchanger.

Basic parameters

The nominal pressure PN of the spiral plate heat exchanger is specified as 0.6, 1, 1.6, 2.5Mpa (that is, the original 6, 10, 16, 25kg/cm2) (refers to the large working pressure that a single channel can withstand) The test pressure is the working pressure 1.25 times.

The material of the contact part of the spiral plate heat exchanger with the medium is Q235A and Q235AF for carbon steel, and SUS321 and SUS304 for stainless steel acid steel. Other materials can be selected according to user requirements.

Allowable working temperature: t=0~+350℃ for carbon steel, t=-40~500℃ for stainless steel acid steel, and the range of heating and pressure reduction is in accordance with the relevant regulations of pressure vessels. When selecting this equipment, proper process calculations should be used to make the fluid in the equipment channel reach a turbulent state. (Generally, the liquid velocity is 1m/Sec and the gas velocity is 10m/Sec).

A single device cannot meet the requirements for use, and multiple devices can be used in combination, but the combination must meet the following requirements:

Parallel combination, series combination: the same distance between equipment and channels.

Mixed combination: One channel is connected in parallel and one channel is connected in series.

Technical parameters of spiral plate heat exchanger

|

Nominal heat transfer area |

Channel spacing |

Carbon steel |

stainless steel |

|

Board thickness |

|

5m² |

6—10 |

4mm |

2~3mm |

|

10m² |

6—10 |

4mm |

2~3mm |

|

20m² |

6—14 |

4mm |

2~3mm |

|

30m² |

10—14 |

4mm |

2~3mm |

|

40m² |

10—14 |

4mm |

2~3mm |

|

50m² |

10—14 |

4mm |

2~3mm |

|

60m² |

14—18 |

4mm |

2~3mm |

|

70m² |

14—18 |

4mm |

2~3mm |

|

80m² |

14—18 |

4mm |

2~3mm |

|

100m² |

14—18 |

4mm |

2~3mm |

|

120m² |

14—20 |

4~5mm |

2~4mm |

|

130m² |

14—20 |

4~5mm |

2~4mm |

|

150m² |

14—20 |

4~5mm |

2~4mm |

|

300m² |

14—20 |

4~5mm |

2~4mm |

SCAN WAPSITE

SCAN WAPSITE